Instrumentation Laboratory Project Page

Project: Hydrostatic Pressure Chamber

Department: Chemical, Paper, and Biomedical Engineering

Primary Investigator: Dr. Jessica Sparks

Purpose:

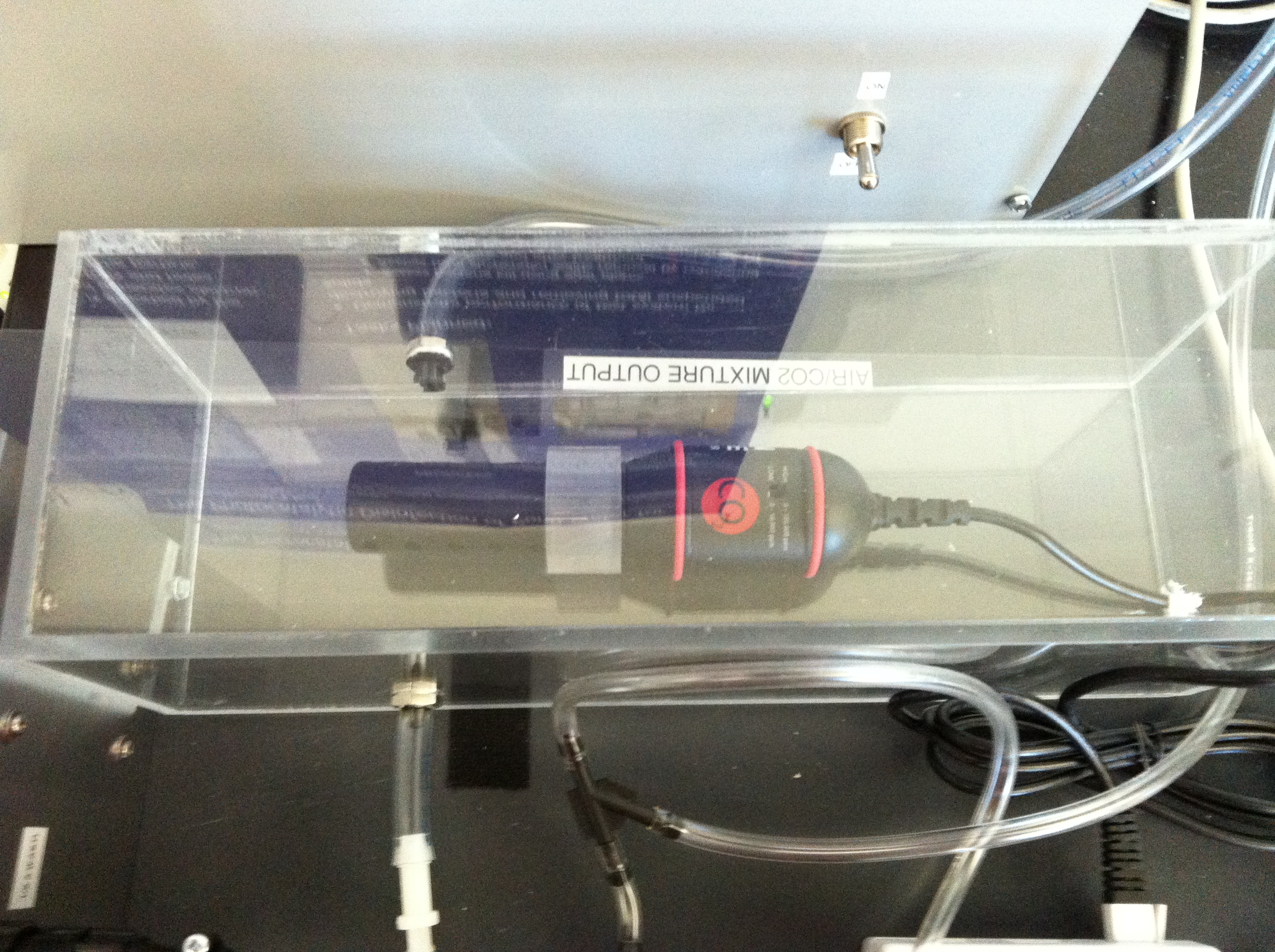

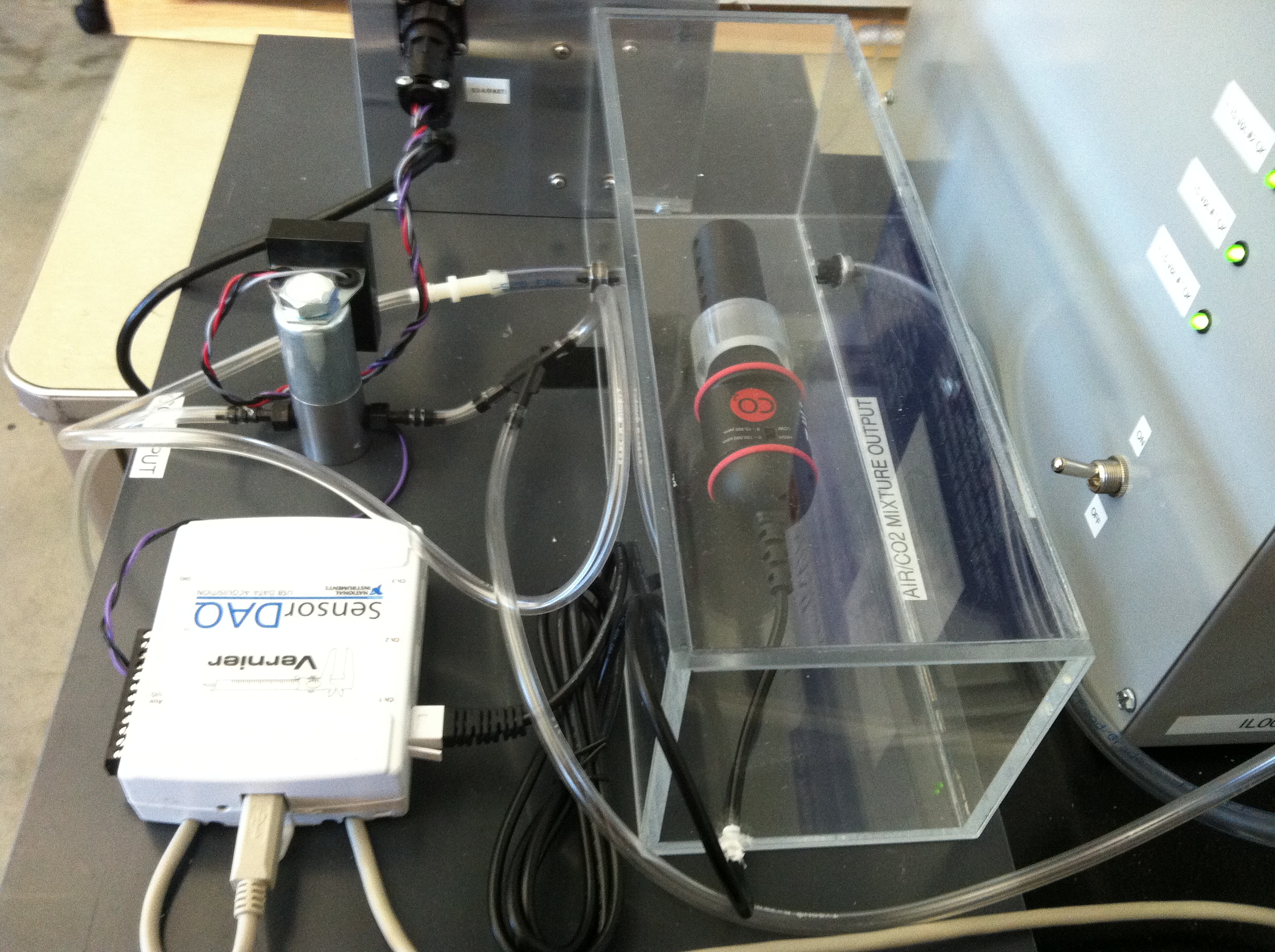

Understanding the biomechanical regulation of liver regeneration could

lead to the development of new treatment strategies for individuals

with chronic liver disease. The purpose of the project is to

investigate the role of mechanical stresses in directing liver

progenitor cell fate. Liver progenitor cells can either mature

into hepatocytes (liver cells) or cholangiocytes (bile duct cells). The

goal is to characterize the effects of hydrostatic pressure on liver

progenitor cell proliferation and differentiation. To do this, we

needed a pressure-controlled cell culture environment. The hydrostatic

pressure system has three chambers which each hold a six-well cell

culture plate and can be disconnected separately to allow for time

points to be taken during experiments. In order to simulate in vivo

conditions, the chambers are stored inside an incubator set at body

temperature, and the system regulates the carbon dioxide concentration

of the air flow to 5%. The air pump, carbon dioxide sensor, and

pressure control unit are placed next to the incubator and are easily

connected to a computer with three USB cables. The IL also designed a

LabView computer program which controls the valves within the system,

monitors the pressure and carbon dioxide levels, and records this data

during experiments.

| |

|

|

|

|

|

| |

|

|

|

|

IL

Comment:

Dr. Sparks approached the I\L with the task of designing and

fabricating a 3 chamber system that would control the pressure in the

chambers at a very low level (0 - 0.58 PSI or 0 - 30 mmHg). The

electronics, chambers, and software were developed and fabricated by

the I\L to accommodate the users' requests while also providing the

ability for potential upgrades in the future (for example, flow

measurement - if needed). The system software was developed using NI

LabVIEW to provide an easy to use instrumentation interface for Dr.

Sparks and the student's in her lab.

After the system was being used in Dr. Sparks' lab, she came back to

the I\L to have a 5% (50 ppm) CO2 concentration system added onto the

existing instrument. The addition of more electronics and software

changes were completed by the I\L to meet this request.

There are commercial systems available to do this type of control at

such low pressures for around $40,000 (minimum); however, none of them

incorporated the CO2 introduction within the same instrument, as this

system does now. During system testing, the instrument was able to

control the pressure within 0.2 mmHg of the desired pressure while

maintaining the CO2 level within 0.2 % of the desired concentration.

Cost to

researcher: $2946.10